Farashin FAF

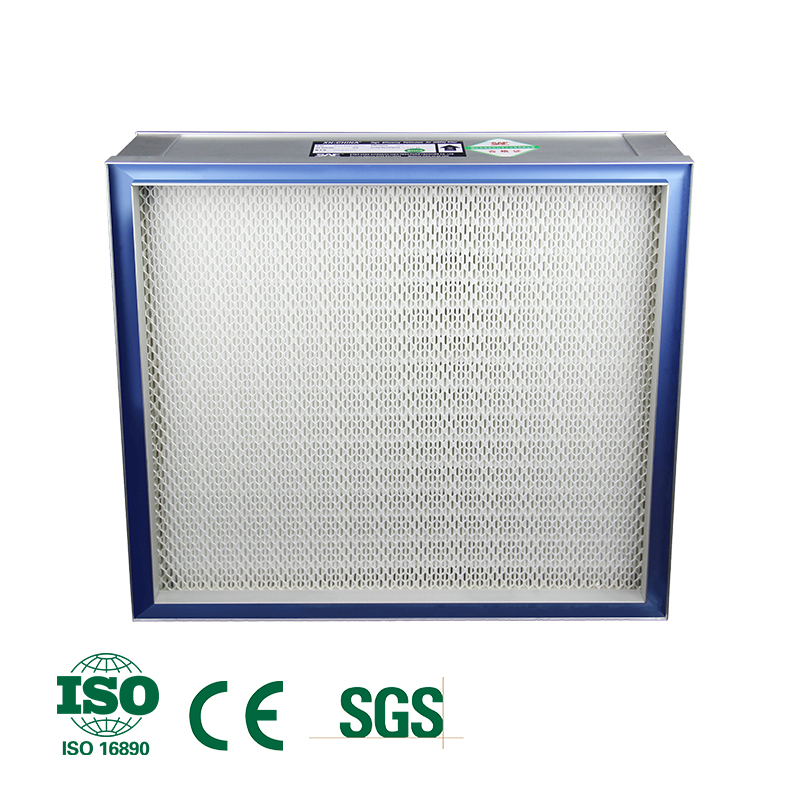

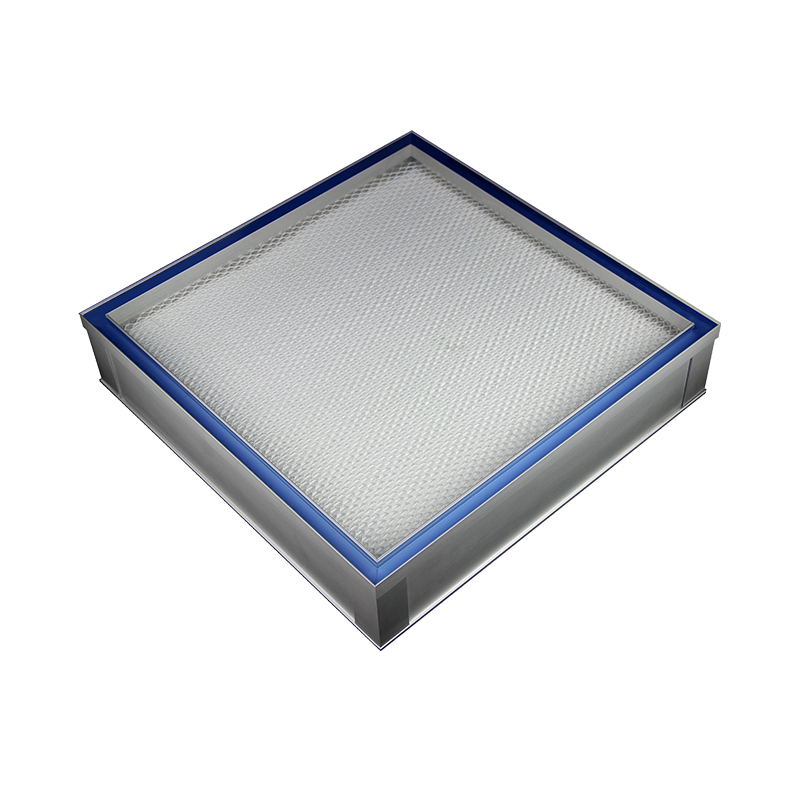

Babban Gel Seal Mini-pleat HEPA tace

Bayanin Samfura

• Mafi ƙarancin 99.99% a 0.3μm, H13, da 99.995% a MPPS, H14.

• Polyalphaolefin (PAO) mai jituwa.

• Matsakaicin mafi ƙanƙanci mai sauke mini-pleat HEPA tace akwai don pharma, kimiyyar rayuwa.

• Galvanized mai nauyi ko aluminum ko firam ɗin bakin karfe akwai.

• Gel, gasket, ko hatimin gefen wuka akwai.

• Thermoplastic zafi-narke separators.

Aikace-aikace na yau da kullun

• Magunguna

• Kimiyyar Rayuwa

• Biosafety

• Kiwon lafiya

• Rufewar kwaya

FAF'S HEPA Tace

An ƙera shi musamman don buƙatu na musamman da ƙalubalen masana'antar harhada magunguna, matatar mini-pleat HEPA tana da tabbataccen ɗorewa, dacewa da polyalphaolefin (PAO), ingantaccen aikin tacewa, da mafi ƙarancin matsin lamba don biyan buƙatun masana'antar harhada magunguna. Shi ne mafi kyawun zaɓi don aikace-aikacen da suka fi buƙata, adana lokaci da kuɗi, yayin da rage haɗarin kamuwa da cuta da ɓarna mara izini. Tare da mafi ƙanƙancin Jimlar Mallakar duk matatun HEPA masu ƙanƙanta, zai taimaka kare yanayin ku, rage haɗarin kasuwancin ku, da haɓaka kashe kuɗin ku mai tsabta.

Tabbatar da Dogara tare da Ayyuka na Musamman

An ƙera shi don haɓaka lokacin ɗaki mai tsafta da rage haɗarin da ke tattare da masana'antar magunguna.

Microglass darajan magunguna, yana ba da kyakkyawan aiki.

Matsakaicin ƙarancin iskar gas na abubuwan sinadaran, yana haifar da ingantacciyar iska mai tsabta da ake samu.

Matsakaicin mafi ƙanƙanta matsi na ƙaramin-pleat HEPA tace akwai, yana rage yawan kuzari don babban tanadi.

Kerarre, gwadawa, da kuma kunshe a cikin wuraren tsabta na ISO 7 don tabbatar da mafi girman tsabta, inganci, da daidaito.

Rage Hadarin Aiki

Masana'antar harhada magunguna sun kiyasta cewa kashi 77% na raguwar lokacin samarwa ana iya danganta su da gazawar kayan aiki da matsalolin muhalli. Wannan raguwar lokaci na iya haifar da gazawar matatar HEPA. Sarrafa yadda ya dace da haɗari da farashin da ke da alaƙa da aiki mai nasara yana buƙatar amfani da matattarar HEPA tare da ƙarfin juriya mai ƙarfi da ƙarfi, ta haka yana kawar da yoyo da gazawa.

Ƙara Uptime

Yayin da Jagororin Gwajin FDA na buƙatar takaddun shaida-gwajin gwaji mai mahimmanci sau biyu a shekara, ɗakunan da ba su da mahimmanci suna buƙatar gwaji sau ɗaya kawai a shekara. haɓaka lokaci tsakanin takaddun shaida yana haifar da ƙarancin bayyanar PAO zuwa hatimin gel (lalacewar gel), ƙarancin farashin aiki, da haɓaka lokacin samarwa.

Makasudin shigar da gwajin ingancin tace HEPA, wanda kuma ake kira gwaji a cikin wurin, shine tabbatar da aiki mara aibi yayin aiki na yau da kullun. Za a iya gwada matattarar FAF'S tare da daidaitaccen photometer na masana'antu a daidaitaccen ma'aunin aerosol, da kuma hanyar ƙarancin aerosol mai hankali Discrete Particle Counter (DPC).

Kashe-Gas ɗin Negligible

Matsakaicin ƙarancin iskar gas na abubuwan sinadaran, yana haifar da ingantacciyar iska mai tsabta da ake samu.